A Series With No Parison Programming

B Series With Parison Programming

Double Station S series

Super Large Series

For Pallet & Pallet Boxes

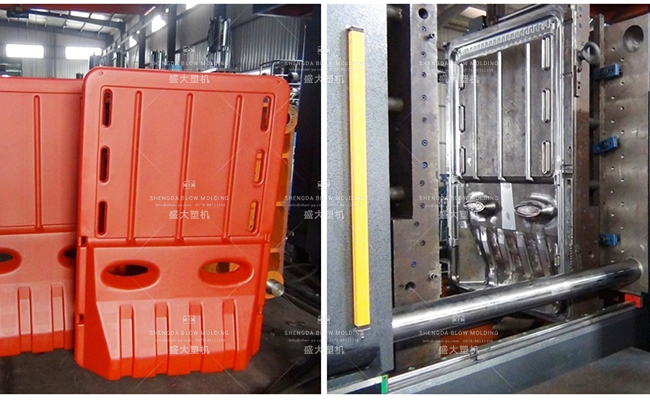

For Road Barricades

For Mannequin

For Barrel & Containers

For Automobile Parts & Toool cases

For Pontons & Solar Floats

For Big Toys & Play Station

For Hospital & Home furtiure

MOULD

Colorful HMI display

PLC Based easy operation

Multipoint parison thickness optimization

Preheat w/o people by PID timing boot

Bigger Platen Size

Linear Potentiometer

Platform with elevator

Harmony Hydraulic System

Nitrided 38 CrMOALA extruder

Safety sensor protection

Energy accumulator low consumption

Quick material changeover

Quick Modular Maintenance

| Technical Parameter | Hot for road cones, posts… | Hot for small/medium sized barriers | Hot for big road barriers and hoardings | ||||||

| SPECS | UNIT | ZK-70A | ZK-70B | ZK-90A | ZK-90B | ZK-100B | ZK-110B | ZK-120B | ZK-135B |

| Max. Product ref. | L | 20 | 25 | 50 | 60 | 120 | 160 | 220 | 1000 |

| Machine Dimension(LxWxH) | M | 4×2.3×2.7 | 4.2×2.3×3.2 | 5×3.1×3.2 | 5×3.1×3.9 | 6.5×3.3×4.4 | 7.5×3.3×4.6 | 7.5×3.2×5.1 | 7.5×3.8×6 |

| Total Weight | Ton | 4.5 | 5.5 | 7 | 9 | 11 | 18 | 22 | 35 |

| Clamping Unit | |||||||||

| Clamping Force | KN | 160 | 160 | 300 | 300 | 500 | 700 | 1200 | 1800 |

| Platen Opening Stroke | mm | 250-850 | 250-800 | 350-1050 | 350-1050 | 400-1400 | 400-1400 | 600-1600 | 600-1800 |

| Max.Mold Size(WxH) | mm | 520×600 | 520×600 | 700×1000 | 700×1000 | 900×1200 | 1050×1600 | 1200×1600 | 1600×2000 |

| Mold Thickness | mm | 260-400 | 250-400 | 360-500 | 360-500 | 410-750 | 410-750 | 610-850 | 610-950 |

| Power | |||||||||

| Hydraulic Motor | KW | 7.5 | 15 | 15 | 15 | 15/22 | 22/30 | 22/37 | 30/45 |

| Total Power | KW | 40 | 53 | 63 | 70 | 85 | 125 | 175 | 260 |

| Fan Power for Screw | KW | 0.72 | 0.72 | 0.72 | 0.72 | 0.72 | 0.72 | 0.72 | 1.08 |

| Air Pressure | Mpa | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 |

| Air Consumption | ㎥/min | 0.9 | 0.9 | 0.9 | 0.9 | 0.9 | 0.9 | 0.9 | 0.9 |

| Average Energy Consumption | KWH | 20 | 25 | 28 | 35 | 38 | 45 | 55 | 80 |

| Extruder Unit | |||||||||

| Screw Diameter | mm | 70 | 70 | 90 | 90 | 100 | 110 | 120 | 135 |

| Screw L/D Ratio | L/D | 25:1 | 25:1 | 25:1 | 25:1 | 30:1 | 30:1 | 30:1 | 30:1 |

| Plasticizing Capacity | KG/HR | 80 | 100 | 100 | 120 | 200 | 240 | 280 | 350 |

| Number of Heating Zone | ZONE | 4 | 4 | 4 | 4 | 5 | 6 | 6 | 6 |

| Extruder Heating Power | KW | 10 | 12.5 | 12.5 | 12.5 | 20 | 36 | 40 | 42 |

| Extruder Motor | KW | 15 | 15 | 22 | 30 | 45 | 55/75 | 75/110 | 110/132 |

| Die | |||||||||

| Number of Heating Zone | ZONE | 3 | 3 | 3 | 5 | 5 | 6 | 6 | 6 |

| Power of Die Heating | KW | 4 | 15 | 7 | 20 | 25 | 36 | 50 | 50 |

| Accumulator Capacity | L | 2 | 4.4 | 5 | 6 | 15 | 20 | 30 | 50 |

| Die Core Diameter | mm | 50-250 | 50-250 | 50-350 | 50-350 | 50-500 | 50-500 | 50-650 | 200-800 |

| Note: The data mentioned above are for reference only. Shengda reserves the rights of modification. Final machine details subject to each specific contract. | |||||||||

Make road barricades easy by blow molding

Indigenous machinery for production of plastic road barriers replacing traditional roto process.

Output rate x 10、HDPE raw material of blow grade for stronger

We consider more for road barricades manufacturing:

Multiple pump arrangement、Multiple blow / pressure / exhaust system、Auto lubrication system、Higher production extruder screw、Long lasting ceramic heater、Safety sensor for operator’ safety、Proximity sensors for blow pins、Hydraulic oil overheating interlock for each power pack、Hydraulic filter clogging interlock for servo power pack

Features of plastic road barricades made by blow molding:

Made from high density material to absorb impact. Used to offer a clear separation of a work zone from vehicular and pedestrian traffic creating clear passage routes, turn areas, entrances and exits throughout the work zone and other city environments. Plastic barriers for traffic and pedestrian separation creates temporary barrier wall that is formidable when filled with water, yet extremely maneuverable when empty.

Application reference:

Traffic Control in Temporary Construction Zones、 Detours on Roadways、 Crowd Control at Sporting Events, Festivals or Other Events、 Demolition Projects、 Airports & Cargo Ports、 Parking Garages …

Add: Jiaoyang Industrial Zone, Airport Road, Jiaojiang District, Taizhou City, Zhejiang Province (north of China Feiyue Group)

Tel:+86-576-88111356

Fax:+86-576-88113168

E-mail:info@zhen-yu.com

Copyright © 2018 Taizhou Shengda Plastic Machinery Co., Ltd. ALL RIGHTS RESERVED浙ICP备14020886号-1Design & Promotion: Feisu.cn